Insulated Pipe Support Blocks to match Mineral Fibre, Nitrile Rubber and Phenolic Foam

Using high quality insulation materials makes sense to everyone, so why would you not use the right pipe support to match your insulation? If the pipe support you are using does not have the same thermal conductivity as the adjacent material (ie your insulation) then this can lead to thermal bridging. Using a pipe block with the same thermal conductivity, or insulation value, vastly reduces the risk of condensation too.

High quality pipe supports can improve the following areas of a system:

- Thermal Insulation

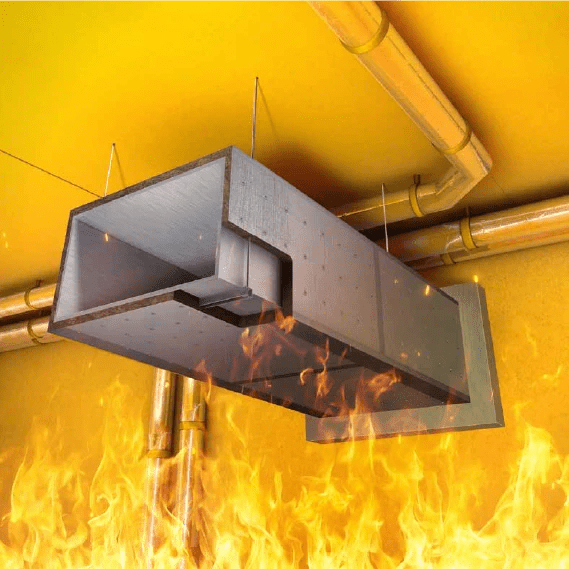

- Fire Performance

- Load Bearing / Point Loading

Insulated Pipe Support Inserts (IPSI) are load bearing insulation products that ensure a continuity of thermal insulation through pipe support brackets; many insulation manufacturers now offer pipe insert systems.

Mineral Fibre Pipe Supports

Knauf Thermo-tek PH INS Pipe Hanger Supports

The Knauf Thermo-tek PH INS Pipe Hanger Support is an insulated pipe support for the reduction of thermal bridges. It consists of a compressive resistant Rock Mineral Wool core for load transfer (INS version = RMW-core only). The core is laminated with tear-resistant multi layer aluminium foil with a self adhesive overlapping seal to close the circumferential opening.

Maximum service temperature 250 °C (EN ISO 18097)

Service temperature aluminium facing ≤ 80 °C

Density ca. 150 kg/m³ (EN ISO 18098)

Application

Mineral Fibre Pipe Hangers (pipe supports) are used to take the weight load of installed pipe work at the fixing joints. Because of their low thermal conductivity they will mitigate thermal bridging to a large effect, in particular on chilled water and other ‚cold‘ lines.

Handling

Knauf Insulation products are easy to handle and easy to install. They are supplied in suitable packaging materials to balance necessary transport protection with sustainable recycling options. Packaging is not designed for long-term storage or exposure to harsh weather conditions. Further product information is mentioned on every pack.

Storage

For longer-term protection on site we recommend storing the product either indoors or alternatively under a roof cover and off the ground. If covered storage is not available, products can be stored outside (open-air-storage) if placed off the ground (keep palletized) and covered with plastic hood (foil), for a maximum of up to 6 months from the date of delivery. Outdoor storage is not recommended during particularly humid months with large fluctuations in temperature.

Phenolic Pipe Supports

SUPAPHEN High Density Phenolic Pipe Supports

The use of factory manufactured phenolic foam insulated load bearing pipe support inserts will greatly reduce the risk of condensation on cold/chilled water pipe applications, providing continuous insulation and vapour resistance as well as enhancing the thermal insulation performance of the system. Supaphen pipe support inserts are manufactured from high density phenolic insulation to suit a full range of diameters and thicknesses covering copper, steel and plastic pipes.

BS5970 2012 Thermal insulation code of practice recommends the use of Insulated pipe support inserts and that the pipe support bracket be fixed over load bearing insulation of the same material (or compatible with) the insulation on the pipe.

Supaphen pipe supports are supplied with a factory applied aluminium foil vapour barrier and are cut to the required length per the table below. A half metal sleeve (or full if required) is applied as standard from 48mm diameter per the table below. Supaphen pipe supports are bore coated in line with major engineering specifications.

Supaphen HD phenolic complies with the requirements of product standard EN14314.

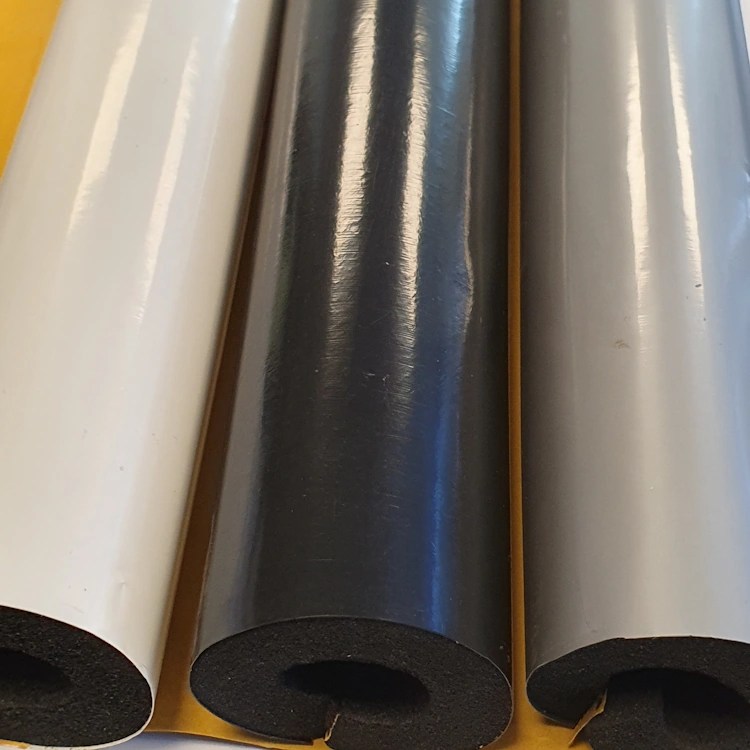

Nitrile Rubber Pipe Supports

Research has shown that uninsulated pipe fittings are still a common thermal bridge on insulated pipe systems. Their effect is often underestimated. A finite element method analysis (FEM) on an insulated pipe section has shown that approximately 50% of the heat loss for the entire considered section is due to the lack of use of pipe supports. It is so easy to avoid thermal bridges.

Specifically designed to ensure a correct insulation thickness where joints are made. The PIR central section, which covers the whole circumference and is attached to two K-FLEX insulating material sections, ensures a perfect continuity of the vapour barrier. Longitudinal sealing is obtained by means of the self-adhesive overlap.

The external cover is in PVC. The support is also available with a collar and a special metal support which, when fixed to the supporting framework, ensures greater overall installation stability.

Thicknesses mm: 13, 19, 25, 32

Tube diameter mm: from 18 to 160; inches: from 3/4” to 5”

The insulating supports are also available in K-FLEX® ECO, SOLAR, AL CLAD, COLOR, in the same measurements as those indicated for K-FLEX® ST

Leave a comment