Our Beginners Guide series of blogs will look at the common areas of pipe insulation lagging that you will want to look at when choosing your product. This guide will be of most interest to the DIY installers, but some of our later guides will cover more complex products and areas of application.

One of the things we get asked about a lot is what the dimensions quoted for pipe insulation actually mean. You will always see three measurements quoted when describing pipe insulation; Wall Thickness, Bore Size and Length.

In the below diagram, A is the “Bore” and B is the “Wall”.

Wall thickness is very simply how much insulation you have; so for example if you have 13mm Wall pipe insulation, then that means you have 13mm of insulation on either side of your pipe. This thickness is very often one of the most important part of your decision; too thin and you might not get the results you are looking for but too thick and it might not fit between your pipe and the wall.

If you have not got much room, but want to prevent your pipes from losing too much heat then you might want to use a 9mm of 13mm wall thickness; this will provide cheap and effective energy savings (though do remember you must seal the insulation properly to prevent gaps where heat will escape). If you have more space and are looking for the maximum efficiency then you may want to use a 25mm Wall to achieve the best results.

A fairly simple rule of thumb (use only as a rough guide) is that for energy loss prevention the bigger the pipe the thicker the insulation as it will have a larger surface area and thus lose heat faster but for frost protection the smaller the pipe the thicker the insulation you will need as a smaller volume of water will freeze more quickly.

Bore size is essentially the hole through which the pipe you are insulating goes. This is the measurement from side to side across your pipe, which is called the diameter of the pipe. Most bore sizes are designed to fit either copper or iron pipe sizes as these are the most common throughout the UK, but if your pipes are plastic then you would normally use the closest size. For example if you have a 25mm plastic pipe, then you would use a 28mm bore pipe insulation; always go a size up rather than a size down. A little extra room is not a problem, but if it is too tight then it may come open even if you seal it with adhesive.

If you want to double check the diameter of your pipe (measuring in tight spaces can sometimes be tricky) then you can measure the circumference of the pipe (the measurement around it) and divide this figure by π, which is roughly 3.14159 if you don’t have that button on your calculator.

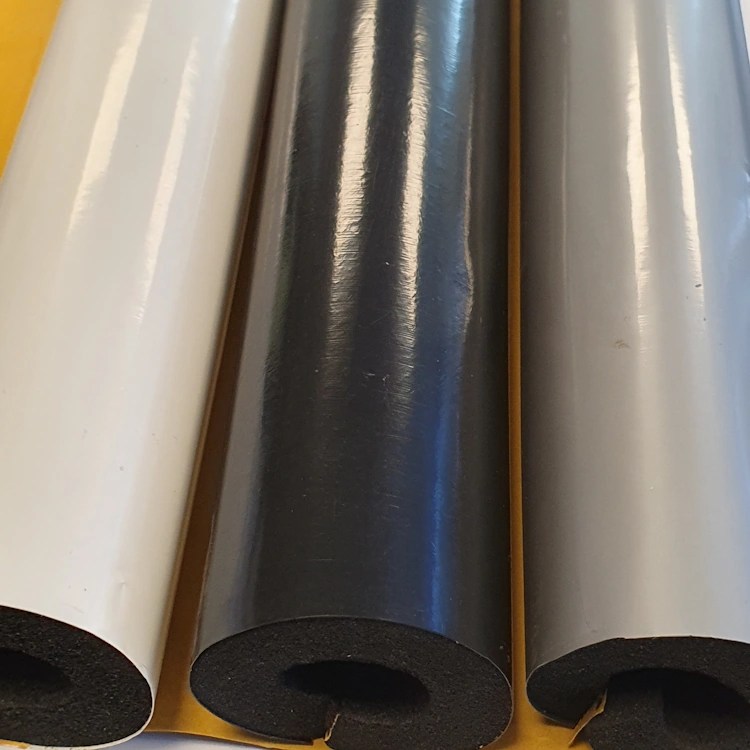

Finally you will want to look at the length of the insulation. “Flexibles” generally come in 2m lengths; these include Climaflex or Tubolit (both also available in 1m lengths), Armaflex and K Flex Lagging.

Rigid pipe sections (generally foil faced) tend to come as either 1m or 1.2m lengths; within our current product range the MW Supaphen Phenolic come as 1m lengths, while Knauf Rock Wool comes as 1.2m lengths.

We will be doing a range of entries on the various kinds of products available as well as jacketing in the coming weeks so watch out for these for more detailed information. In the meantime we have a handy reference table below as a quick guide to the products we offer.

| Product | Internal Use | External Use | Key Benefits |

| Polyethylene | ✔️ | ❌ | Cheap, Easy to Use, Flexible |

| Nitrile Rubber | ✔️ | ❌ | Class 0 / Euro Class B, Very Flexible |

| Rock Mineral Wool | ✔️ | ❌ | Foil Faced, High Temp, Good for steam pipes |

| Glass Mineral Wool | ✔️ | ❌ | Foil Faced, High Temp, Good for heating pipes |

| Phenolic Foam | ✔️ | ❌ | Foil Faced, Very Low thermal conductivity |

| High Temp Rubber | ✔️ | ✔️ | Can be used up to 150°C, Can be used outside |

| Coated Nitrile Rubber | ✔️ | ✔️ | Protective plastic skin, waterproof, UV resistant |

Leave a comment